EnerSpan® 30 Insulation

EnerSpan 30 insulation is manufactured using Neopor® provided by BASF, a graphite-enhanced raw material that reduces radiation heat transfer resulting in higher thermal resistance (R-value) compared to standard CAN ULC S701.1, Type 3 EPS insulation.

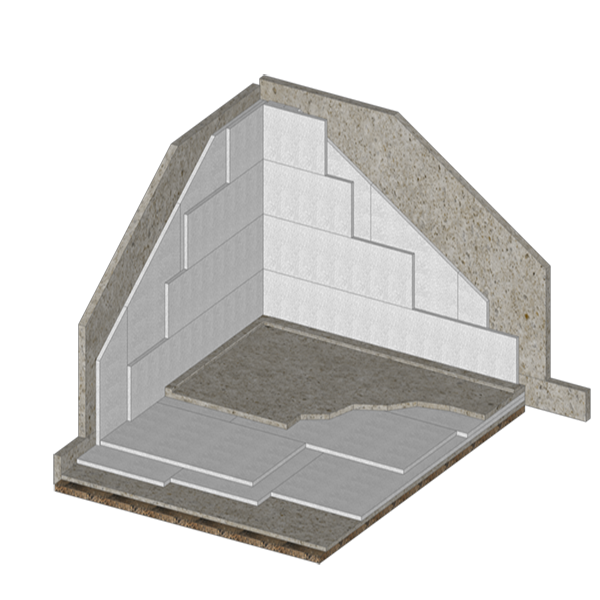

With an R-value of 4.7 per inch, EnerSpan 30 helps you achieve your desired R-value with a thinner board. EnerSpan 30 insulation is easy to work with and install, and consistently delivers the highest true R-value performance over time. This high-performing insulation is breathable, while the closed-cell structure does not support the growth of mold, while adapting to all climate zones. With the higher compressive strength of 30 psi, EnerSpan 30 is a versatile insulation product that can be used in a wide range of applications, but it ideal when higher compressive resistance is required.

EnerSpan 30 insulation’s minimum compressive resistance of 30 psi makes it ideal to insulate low temperature freezer floors or for use in other applications where moderate loads are expected. By incorporating EnerSpan 30 insulation into your project as a continuous insulation solution, you are able to eliminate thermal bridging; increasing your total effective RSI/R-value, effectively reducing energy costs and increasing your energy savings.

Available in 2x8 ft. and 4x8 ft., 2 ft. high bundles

Thicknesses of ¾, 1, 1 ½, 2, 2 ½ , 3, 3 ½ , 4 inches, Plus special order sizes and thickness to meet job

- Meets all building code requirements

- Compressive Resistance of 30 psi

- Thermal resistance of True R-value of 4.7 per inch

- Closed cell insulation resists moisture

- Easy to cut and install

- Permanent R-value

- Increases energy efficiency for reduced heating and cooling costs

- Can be used for retrofit or new construction

- Uses up to 30% less material than other rigid foam insulation to achieve the same R-value, saving on building materials and installation labor

- Thinner boards are needed to reach the desired R-value than others so the same effect is achieved with less material

Material Properties of EnerSpan® 30 Insulation

| Material Property | Units | CAN/ULC-S701 Type | ||

|---|---|---|---|---|

| 1 | 2 | 3 | ||

|

Thermal Resistance Minimum RSI per 25mm (inch) ASTM C518 |

m2 • 0C/W (ft2•h•0F/BTU) |

0.82 (4.7) |

0.82 (4.7) |

0.82 (4.7) |

|

Compressive Resistance Minimum @ 10% Deformation ASTM D1621 |

kPa (psi) |

70 (30) |

110 (16) |

170 (25) |

|

Flexural Strength Minimum ASTM C203 |

kPa (psi) |

170 (25) |

240 (35) |

300 (44) |

|

Water Vapour Permeance Maximum ASTM E96 |

ng/(Pa.s.m2) (Perms) |

300 (5.2) |

200 (3.5) |

130 (2.25) |

|

Water Absorption Maximum ASTM D2842 |

% By Volume | 6.0 | 4.0 | 2.0 |

|

Dimensional Stability Maximum, 7 Days @ 70± 2℃ (158±40F) ASTM D2126 |

% Linear Change | 1.5 | 1.5 | 1.5 |

|

Limiting Oxygen Index Minimum ASTM D2863 |

% | 24 | 24 | 24 |

|

Surface Burning Characteristics Classification or Rating CAN/ULC S102.2 |

Flame Spread Smoke Developed |

220 over 500 |

||