EnerSpan® 20 Insulation

EnerSpan 20 insulation is manufactured using Neopor® provided by BASF, a graphite-enhanced raw material that reduces radiation heat transfer resulting in higher thermal resistance (R-value) compared to standard CAN ULC S701.1, Type 2 EPS insulation.

With an R-value of 4.7 per inch, EnerSpan 20 helps you achieve your desired R-value with a thinner board. EnerSpan 20 insulation is easy to work with and install, and consistently delivers the highest true R-value performance over time. This high-performing insulation is breathable, while the closed-cell structure does not support the growth of mold, while adapting to all climate zones. With the higher compressive strength of 20 psi, EnerSpan 20 is a versatile insulation product that can be used in a wide range of applications, but it ideal when higher compressive resistance is required.

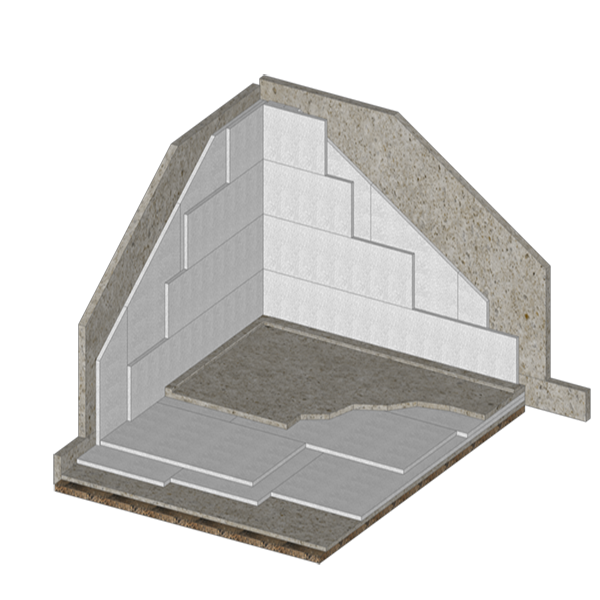

EnerSpan 20EPS is a closed cell, rigid foam plastic insulation that maintains its R-value for the life of the product. When applied as continuous insulation over foundations, walls and roofs, EnerSpan 20 insulation is a cost-effective solution that eliminates thermal bridging, increasing your total R-value.

Available in 2x8 ft. and 4x8 ft., 2 ft. high bundles

Thicknesses of ¾, 1, 1 ½, 2, 2 ½ , 3, 3 ½ , 4 inches, Plus special order sizes and thickness to meet job

- Meets all building code requirements

- Compressive Resistance of 20 psi

- Thermal resistance of True R-value of 4.7 per inch

- Closed cell insulation resists moisture

- Easy to cut and install

- Permanent R-value

- Increases energy efficiency for reduced heating and cooling costs

- Can be used for retrofit or new construction

- Uses up to 30% less material than other rigid foam insulation to achieve the same R-value, saving on building materials and installation labor

- Thinner boards are needed to reach the desired R-value than others so the same effect is achieved with less material

Material Properties of EnerSpan® 20 Insulation

| Material Property | Units | CAN/ULC-S701 Type | ||

|---|---|---|---|---|

| 1 | 2 | 3 | ||

|

Thermal Resistance Minimum RSI per 25mm (inch) ASTM C518 |

m2 • 0C/W (ft2•h•0F/BTU) |

0.82 (4.7) |

0.82 (4.7) |

0.82 (4.7) |

|

Compressive Resistance Minimum @ 10% Deformation ASTM D1621 |

kPa (psi) |

70 (20) |

110 (16) |

170 (25) |

|

Flexural Strength Minimum ASTM C203 |

kPa (psi) |

170 (25) |

240 (35) |

300 (44) |

|

Water Vapour Permeance Maximum ASTM E96 |

ng/(Pa.s.m2) (Perms) |

300 (5.2) |

200 (3.5) |

130 (2.25) |

|

Water Absorption Maximum ASTM D2842 |

% By Volume | 6.0 | 4.0 | 2.0 |

|

Dimensional Stability Maximum, 7 Days @ 70± 2℃ (158±40F) ASTM D2126 |

% Linear Change | 1.5 | 1.5 | 1.5 |

|

Limiting Oxygen Index Minimum ASTM D2863 |

% | 24 | 24 | 24 |

|

Surface Burning Characteristics Classification or Rating CAN/ULC S102.2 |

Flame Spread Smoke Developed |

220 over 500 |

||